The world is hurtling towards a clean energy future, and at the heart of this transformation lies battery technology. From powering electric vehicles (EVs) to enabling large-scale integration of renewable energy sources like solar and wind, advanced batteries are the backbone of a sustainable tomorrow. India, with its burgeoning population and ambitious clean energy goals, finds itself at a critical juncture. To secure its energy future and emerge as a global leader, India must focus on developing robust “Make-in-India” battery solutions.

The Lithium-ion Conundrum

The current undisputed king of the battery world is the lithium-ion battery. Its high energy density, relatively long lifespan, and ability to be recharged make it ideal for a wide range of applications. However, there are limitations. Lithium, a key component, is a finite resource with geographical constraints. Additionally, the environmental impact of lithium mining and battery disposal raises concerns. Furthermore, the cost of lithium-ion batteries remains a barrier for wider adoption in EVs and energy storage applications.

The Quest for Alternatives

Recognizing these limitations, researchers worldwide are exploring alternative battery technologies. Some promising contenders include:

Sodium-ion batteries: These batteries offer a lower energy density than lithium-ion but boast advantages like wider material availability (sodium is abundant) and potentially lower costs.

Solid-state batteries: Replacing the flammable liquid electrolyte in lithium-ion batteries with a solid alternative promises enhanced safety, faster charging times, and potentially longer lifespans.

Redox flow batteries: These batteries store energy in liquid solutions and are ideal for large-scale energy storage applications due to their scalability and long lifespans.

India’s Make-in-India Opportunity

While established players dominate the lithium-ion battery market, India has a unique opportunity to carve a niche in the development and manufacturing of next-generation battery technologies. Here’s why:

Resource Advantage: India has abundant reserves of key materials for alternative batteries, like sodium and vanadium (used in Redox flow batteries). This reduces dependence on foreign imports and provides a cost advantage.

Government Push: The Indian government has recognized the strategic importance of battery technology and launched initiatives like the “Mission for Accelerating Development in Battery Storage for Electric Vehicles” (Faster Adoption and Manufacturing of Electric Vehicles in India Scheme – FAME) to incentivize domestic battery production.

Research & Development: India boasts a growing pool of scientific talent and research institutions actively engaged in battery technology development. This indigenous knowledge base is crucial for innovation and creating a self-reliant battery ecosystem.

Challenges and the Path Forward

Despite the potential, India faces challenges in its Make-in-India battery mission:

Technological Gap: Established players have a head start in terms of research and manufacturing capabilities. India needs to bridge this gap through increased investment in R&D and collaboration with international players.

Skilled Workforce: Building a skilled workforce for battery design, manufacturing, and recycling is critical. India needs to develop targeted training programs to bridge the skill gap.

Sustainable Practices: Mining and processing of battery materials can have environmental consequences. India needs to establish robust regulations and invest in sustainable practices throughout the battery lifecycle.

The Road Ahead

India’s success in the battery sector hinges on a multi-pronged approach:

Continued Government Support: Sustained government support through policy initiatives, financial incentives, and infrastructure development is crucial to create a conducive environment for battery manufacturing.

Public-Private Partnerships: Collaboration between government, research institutions, and private companies can accelerate innovation and commercialization of indigenous battery technologies.

Focus on Innovation: Investing in R&D of next-generation battery technologies beyond lithium-ion will position India as a leader in the clean energy revolution.

Conclusion: Powering a Greener Future

Developing a robust Make-in-India battery ecosystem presents a win-win situation for India. It can not only address its domestic energy needs and fuel its clean energy ambitions but also emerge as a global player in the battery technology market. By overcoming challenges and focusing on innovation, India can harness the potential of battery breakthroughs to power a sustainable and prosperous future.

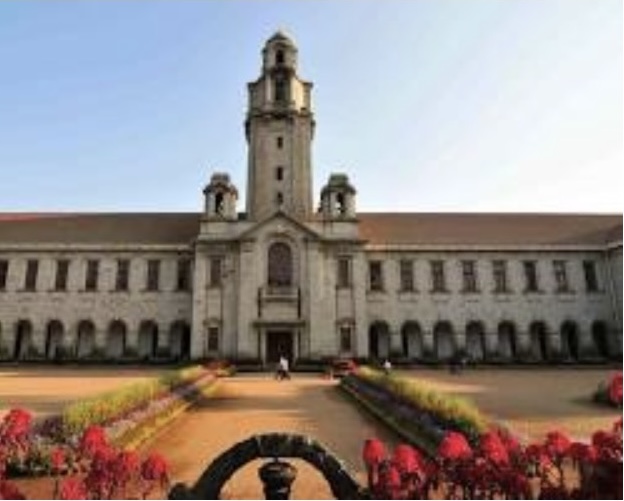

Indian Institute of Science (IISc Bangalore): IISc Bangalore is a premier research institute in India with a strong focus on battery research. Their Electrochemical Energy Materials Laboratory is known for its work on lithium-ion batteries, sodium-ion batteries, and solid-state batteries.

Council of Scientific and Industrial Research (CSIR):

CSIR, an autonomous body under the Department of Science and Technology, has several laboratories working on battery technologies. Notably, the Central Electrochemical Research Institute (CECRI) is developing indigenous lithium-ion battery technology for electric vehicles.

Tata Chemicals Ltd.:

This major Indian chemicals company is heavily invested in lithium-ion battery technology. They have set up a cell manufacturing plant and are working on research and development for next-generation batteries.

Exide Industries Ltd.:

A household name in India for batteries, Exide Industries is also working on advanced battery technologies for electric vehicles and grid storage applications.

Honeywell India:

The Indian arm of the global conglomerate Honeywell is developing advanced lithium-ion battery materials for electric vehicles and aerospace applications.

These are just a few examples, and there are many other companies and institutions in India making significant contributions to battery technology development. Their efforts are crucial for India’s ambitions in the electric vehicle sector and clean energy transition.